What Does Kawneer Spandrel Panel Metal Spandrel Do?

Table of ContentsLittle Known Facts About Spandrel Panel Window.The Best Guide To Storefront PanelsAbout Kawneer Spandrel Panel Metal SpandrelOpaque Spandrel Panels Things To Know Before You BuySpandrel Glass Panel for BeginnersEverything about Insulated Panels

Occasionally, there are concerns connecting to having excessive uncontrolled daylight, often described as glow. The difficulty is to pursue the highest noticeable light passage (VT) and also the most affordable solar heat gain coefficient (SHGC) while not avoiding the glass from being too reflective when seen from both the exterior as well as the inside, while controlling glow.The devices need to be entirely constructed in a factory as well as shipped to the website for setup on the building. The units are put on the floors, bundled in dog crates, utilizing the tower crane and also reduced into place making use of a smaller crane or lift owned by the glazing contractor. The mullion measurements have a tendency to be slightly larger than a stick system because of their open section as contrasted to the tube shape of a standard stick curtain wall surface section.

Units can be assembled in a factory while the architectural structure of the structure is being constructed. Where stick systems need numerous actions to erect and also seal the wall surface, unitized walls show up on the site totally assembled allowing the floors to be enclosed quicker. Unitized systems likewise call for much less room on website for layout thus offering an advantage for urban sites with area constraints.

The Single Strategy To Use For Opaque Spandrel Panels

Solutions whose attaching legs lock likewise endanger the capability of the system to fit activity. Some unitized designs are sensitive to small irregularities in the spacing of nearby components; for instance, if the component joints are a little out of resistance, gaskets might not be properly compressed as well as dampness protection may endure.

This is where field labor must secure in between nearby devices to attain a climate tight wall surface. The interlocking legs of the straight mullions are the most essential interface of a unitized system.

Rumored Buzz on Nhbc Spandrel Panels

These upstanding legs have gaskets that secure versus the walls of the lower horizontal. Extra robust systems will provide 2 upstanding legs with gaskets on both legs.

The pile joint is the horizontal joint where devices from adjoining floorings fulfill. Putting the pile joint at the sill of the vision glass (typically 30" above the floor) will certainly reduce the measurement of the upright mullions. This positioning panel glasliner utilizes the back span of the mullion over the anchoring point at the piece to combat the deflection of the mullion listed visit the site below the piece.

Specify that lab examinations are to be conducted at an AAMA Accredited Laboratory center. Area Mock-up: For all curtain wall surfaces, stock or customized, need construction and screening of an area mock-up representative of the wall/window setting up. This is finest set up before the release of shop illustrations for home window manufacturing, so that there is a possibility to make design modifications based upon the examination performance of the field mock-up.

The Single Strategy To Use For Spandrel Panel Window

Area screening of curtain walls: Require the field testing of drape walls for air infiltration and water penetration resistance, for quality control of curtain wall fabrication and also setup. Require multiple examinations with the very first test on initial setups as well as later examinations at around 35%, 70% as well as at final completion to catch troubles early and also to confirm continued workmanship high quality.

The information connected with this area of the BEDG on the WBDG were established by committee and are planned exclusively as a way to show basic layout and also building and construction principles only. Ideal use and also application of the concepts highlighted in these information will certainly differ based on performance factors to consider as well as ecological conditions special to each project and, as a result, do not represent the last viewpoint or referral of the writer of each area or the board participants responsible for the development of the WBDG.

Continual steel sill flashing at the base of the curtain wall shields the wall surface framing listed below from leakage via the curtain wall surface. Sill blinking must have upturned end dams and also fully sealed edges. Intermediate horizontal must be cried to the outside why not find out more and also avoid water from draining pipes onto the head of the glazing unit listed below.

Not known Facts About Insulated Panels

Spandrel glass adapters are used to lower the depth of the glazing pocket to fit decreased profile of spandrel glass. Spandrel glass adapters must be fully bedded in sealer as well as integrated with glazing pocket corner seals to stop water leak from polishing pocket to structure inside. System dimension of mating head and sill extruded accounts permits specified flooring to flooring deflection at the pile joint.

Intermediate horizontals quit at the face of the upright device jamb participants at each end. Devices are hung from the leading or face of the adjacent floor or building structure making use of mated braces and also field used bolts with a minimum of clearance for gain access to as well as setting up. All links and brackets situated within the systems insulated or key climate seal zones are secured with appropriate sealer materials throughout field installation.

Opaque Spandrel Panels Fundamentals Explained

non-heat-treated) or fully solidified glass to remain in place up until it can be changed. Whether heat-strengthened or totally toughened up, heat-treated glass items are produced in a similar style and also making use of the same processing devices. The glass is heated to roughly 650 C (1200 F), after that force-cooled to develop surface as well as edge compression.

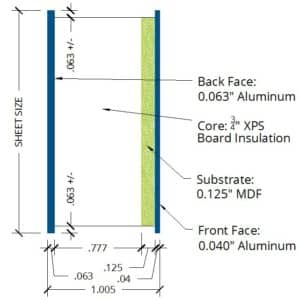

As shown in Figure 1, insulation is typically made use of in conjunction with spandrel glass. When the insulation is to be applied directly to the opacified surface of the spandrel glass, it is necessary to deal with a glass spandrel producer, as well as the glue and insulation suppliers, to make certain these products work with the opacifying product - storefront panels.